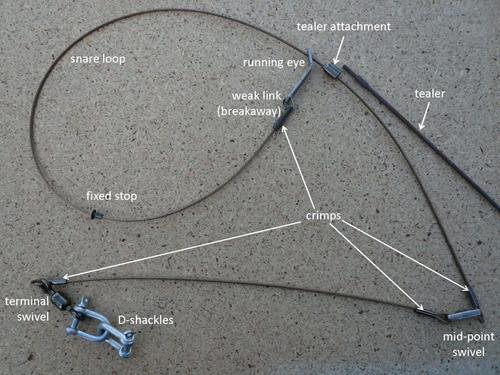

Because snares are such minimalist devices, crucial features are very small details with inter-related functions. Here we describe each component in turn.

Wire cable

A cable that is too flexible will form a floppy snare loop that requires a lot of support. Such a soft wire will also abraid easily when fretted against other objects. Cable that is too stiff may cause the snare loop to spring open again (releasing the fox), and will not be durable under repeated flexing by a captured animal. The ideal is a compromise between these two extremes. There are many cable constructions to choose from. Cable thickness is also a compromise: thin cable is less visible but thick cable is stronger and less damaging to the captured animal. The length of cable in a snare should be kept to a minimum: slack allows a captured animal to run, risking nasty injuries and escapes, and increases the risk of the snare becoming entangled. According to both the Defra CoP and the Scottish CoP, snare cable must have a breaking strain of at least 460lbs (208kgs). As far as we know, this is the case for all steel cable of 2mm diameter as normally used for fox snares. If it’s less than 2mm you should check the specs from the cable manufacturer.

Crimps

Cable is joined to other components using a crimp of softer or harder metal applied with a press. Crimping can be done effectively using hand tools, but components must be well matched in dimensions with each other and with the dies of the tool. Experience also affects crimp strength.

If a crimp were to give way in use, or if the cable broke, a captured animal might escape with the snare fast around part of its body. Given effective swivels (see below), such breakages are rare in practice, but can lead to prolonged suffering and a slow death in the escaping animal. To avoid this rare but nasty event, the crimp at the noose eye (or the eye itself) can be designed to break at a specified lower force than other crimps on the snare, ensuring that no escaping animal can make off with the noose attached. This is a requirement under the Defra CoP. An extension of this idea is to fit a weak link or ‘breakaway’ at the eye, designed to open at a predetermined strain.

Swivel

If a captured animal repeatedly rolls in the same direction, the snare cable will either unravel or become over-wound. If the wire unravels, the separated strands of wire are easily snapped or chewed through. If the cable is over-wound, it is weakened by torque and it may snap. To prevent either from occurring, snares should be fitted with swivels. We recommend that snares are fitted with two swivels. The main swivel should be located at the tail-end of the snare where it can be attached to the anchor point (which helps make it turn) using a ‘D’ shackle. In case this swivel should become fouled with soil or entangled in vegetation, we recommend that another ‘in-line’ swivel is fitted midway along the snare, thus ensuring the snare always includes at least one functional swivel.

If a captured animal repeatedly rolls in the same direction, the snare cable will either unravel or become over-wound. If the wire unravels, the separated strands of wire are easily snapped or chewed through. If the cable is over-wound, it is weakened by torque and it may snap. To prevent either from occurring, snares should be fitted with swivels. We recommend that snares are fitted with two swivels. The main swivel should be located at the tail-end of the snare where it can be attached to the anchor point (which helps make it turn) using a ‘D’ shackle. In case this swivel should become fouled with soil or entangled in vegetation, we recommend that another ‘in-line’ swivel is fitted midway along the snare, thus ensuring the snare always includes at least one functional swivel.

We like neat, small swivels: a bulky mid-point swivel spoils the natural line of the snares and makes an obvious and ugly visual distraction. However, experience tells us that very simple devices made of bent metal plates do not function very well. Small, well-engineered ‘in-line’ swivels, perfectly designed for this job, are available from a number of retail outlets selling snare components.

Eye

This is the part that slides along the wire to form the running noose. By law it must not be self-locking, as explained under ‘What snares to use’, but to hold the captured animal the eye must have enough friction to prevent the snare loop springing open again after closing. This is why definition of the terms ‘self-locking’ and ‘free-running’ is so difficult. Pulling by hand on the eye or on the cable near the eye does not adequately simulate the expanding movement of a breathing animal, which will tilt the eye over at a different angle.

This is the part that slides along the wire to form the running noose. By law it must not be self-locking, as explained under ‘What snares to use’, but to hold the captured animal the eye must have enough friction to prevent the snare loop springing open again after closing. This is why definition of the terms ‘self-locking’ and ‘free-running’ is so difficult. Pulling by hand on the eye or on the cable near the eye does not adequately simulate the expanding movement of a breathing animal, which will tilt the eye over at a different angle.

From all points of view, it is important that the section of snare cable over which the eye slides does not become rusty, as this will impair the movement of the eye. If rust prevents the noose closing swiftly, a fox might easily withdraw its head from the noose and escape. If rust prevents the eye sliding open easily, it may render an otherwise legal snare ‘self-locking’ and therefore illegal. We would expect this to happen progressively, rather than overnight, but exactly where the point lies at which the snare should be considered self-locking is not clear. It’s something that only the courts can decide. Our advice is to assume that someone will trip you up if they can, and err on the side of caution: replace the snare before it’s too late.

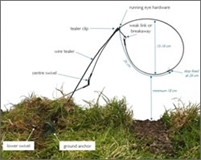

Stop

The stop is a very small crimp that prevents the noose closing beyond a predetermined diameter, to prevent injury or death by strangulation, and also to prevent the capture of deer by the foot. Some snares are still sold with a stop that is not fixed allowing operators to choose their own minimum loop size. In practice most operators in the past chose to ignore it, or didn’t know what it was for. In England and Wales there is no legal requirement to use a stop, but it is recommended in the CoP, which suggests that the stop should be fixed ‘approximately’ 23cm (9”) from the snare eye. In Scotland a stop must be used (Snares (Scotland) Order 2010), and in a sensible clarification the wording says that the stop must be fitted ‘at least’ 23cm (9”) from the eye.

The stop is a very small crimp that prevents the noose closing beyond a predetermined diameter, to prevent injury or death by strangulation, and also to prevent the capture of deer by the foot. Some snares are still sold with a stop that is not fixed allowing operators to choose their own minimum loop size. In practice most operators in the past chose to ignore it, or didn’t know what it was for. In England and Wales there is no legal requirement to use a stop, but it is recommended in the CoP, which suggests that the stop should be fixed ‘approximately’ 23cm (9”) from the snare eye. In Scotland a stop must be used (Snares (Scotland) Order 2010), and in a sensible clarification the wording says that the stop must be fitted ‘at least’ 23cm (9”) from the eye.

So 23cm should be regarded as the minimum throughout the UK. However, it turns out that a stop set even further from the eye has other benefits. In a recent field-trial by professional gamekeepers, we compared capture rates of ‘off-the-shelf ’ fox snares against snares with stops fixed at 26cms. In the south of England, where foxes are as small as anywhere in the UK, we measured the head circumferences of adult vixens of various weights which had been collected by night shooting. The smallest noose we could force over the head of the smallest (4.0kg) adult vixen was 25cm in circumference. Ninety five percent of the adult vixens we measured had heads bigger than this. In practice, it seems that live foxes do not pull as hard as we did, perhaps because their ears get in the way. Given a stop set at 26cm, the smallest fox retained during the course of the trial was a juvenile vixen of 3kg.

Fox escapes were equally rare whether the stop was set at 23cm or 26cm, but hare captures were greatly reduced using the 26cm setting. Additionally, the longer stop position made it much easier to release any badgers caught, because the wire was drawn less tightly against the neck of the animal.

The ideal stop position will clearly be a compromise between achieving all these benefits and retaining captured foxes. We don’t yet know exactly where that is, but we have begun to use snares with even longer stops on a trial basis. Watch this space!

Data from practising gamekeepers suggests that with any type of snare you can expect 5-10% of captured foxes to escape, perhaps because the noose didn’t draw up behind the ears. Don’t worry about this: provided you leave no scent or other clues around your snares, you will re-catch those escapees. We are confident about this, because of the ease with which we can re-capture foxes that have already been snared, handled and radio-tagged.

Tealer

The snare needs some kind of support. It is usually supported by a rigid stick or wire ‘tealer’ at one side of the run on which it is placed. The ‘old school’ approach uses a short stick of hazel or similar wood as a tealer, split at the top to hold the cable. This is a local natural material, after all. The downside is that in cutting, sharpening and planting the stick you can’t avoid leaving human scent on the tealer, which has plenty of surface area to hold it. Our infra-red camera studies of fox behaviour have verified that foxes avoid sticks that have been rubbed with human scent, so we favour a wire tealer, 2-3mm thick, which can be boiled with the snares to remove scent and is easily pushed into the ground and bent to the required shape. Our ideal is copper wire. Copper acquires an oxidised surface colour that blends in magically almost anywhere. It is more easily bent to shape than steel wire. Although initially expensive, copper tealers last a lifetime.

The snare needs some kind of support. It is usually supported by a rigid stick or wire ‘tealer’ at one side of the run on which it is placed. The ‘old school’ approach uses a short stick of hazel or similar wood as a tealer, split at the top to hold the cable. This is a local natural material, after all. The downside is that in cutting, sharpening and planting the stick you can’t avoid leaving human scent on the tealer, which has plenty of surface area to hold it. Our infra-red camera studies of fox behaviour have verified that foxes avoid sticks that have been rubbed with human scent, so we favour a wire tealer, 2-3mm thick, which can be boiled with the snares to remove scent and is easily pushed into the ground and bent to the required shape. Our ideal is copper wire. Copper acquires an oxidised surface colour that blends in magically almost anywhere. It is more easily bent to shape than steel wire. Although initially expensive, copper tealers last a lifetime.

Various materials have been used to hold the snare to a wire tealer. These include spiral plastic cable-wrap (‘Spirawrap’, available in several colours), or a simple twist of gardener’s wire. Ideally, though, the snare can be lifted off the tealer easily. This makes it easy to set the snare, or to ‘un-set’ it for a night off, leaving tealer and anchor in position. It also means that the captured animal cannot get the snare cable entangled with the tealer. Tealer-clip components that attach the snare to the tealer, but still ‘pivot’ freely, also allow the snare to ‘reset’ itself if something brushes underneath.

Anchor

The snare anchor must be effective at holding not only a fox, but any non-target animal that might be caught. There is no single anchor type that will suit all ground conditions. For the majority of conditions, we recommend a 450mm x 25mm length (18” x 1”) of 5mm thick angle-iron, driven into the ground. An 8mm hole should be drilled 50mm from the top, in the middle of one side of the angle iron. Connect a 50mm diameter welded ring to a D-shackle, and fix the shackle to the stake via the drilled hole. The snare should be attached to the ring, with another D-shackle. This arrangement acts almost like a universal joint and is unlikely to foul the anchor. Whenever you use D-shackles, make sure they are tightened using pliers.

The snare anchor must be effective at holding not only a fox, but any non-target animal that might be caught. There is no single anchor type that will suit all ground conditions. For the majority of conditions, we recommend a 450mm x 25mm length (18” x 1”) of 5mm thick angle-iron, driven into the ground. An 8mm hole should be drilled 50mm from the top, in the middle of one side of the angle iron. Connect a 50mm diameter welded ring to a D-shackle, and fix the shackle to the stake via the drilled hole. The snare should be attached to the ring, with another D-shackle. This arrangement acts almost like a universal joint and is unlikely to foul the anchor. Whenever you use D-shackles, make sure they are tightened using pliers.

Corkscrew and spiral ground anchors are also effective, but expensive. The length needs to be chosen to suit local ground conditions. Some operators report single-use earth anchors (e.g. Duck-Bills) as useful in certain ground conditions, such as on moorland. We do not recommend the use of smooth metal rods – these can easily be pulled out, especially when the ground is wet. Whatever type of anchor you use, the top of it should be more or less flush with ground level, to prevent the captive winding the snare around it. Do not attach snares to posts or natural objects such as trees or saplings – this encourages entanglement which may result in injury or death.

An angle iron anchor stake (left) and a corkscrew anchor (right) in position

It has formerly been common practice to fasten a snare to a ‘drag’: a heavy weight such as a log which allows the captured animal to move away from the capture site until it becomes arrested by entanglement. The main arguments proposed in favour of the drag were that it allowed the animal to find cover where it will feel less stressed; that it causes less physical injury than the dead resistance of a ground anchor does; and that it preserves the capture site undisturbed for re-use. The use of drags has now been prohibited in Scotland. In England and Wales, we recommend you do not use a drag, chiefly because you cannot fulfil your obligations under the Animal Welfare Act towards a captured animal if you don’t know for certain where it is. There is no guarantee that the captive animal on a drag will ever be found. Also, even if the animal is reassured by gaining cover, entanglement greatly increases the risk of physical suffering before dispatch. A drag which can be moved by a fox may allow a stronger non-target species to travel a considerable distance.

NB – The 2009 edition of the Scottish CoP recommended that an anchor weight should weigh more than 45lb (20kg). We believe this is too light to form an immoveable anchor for the whole range of species that might be caught, while heavier weights would really be unmanageable. Drags have now been prohibited in Scotland by the Snares (Scotland) Order 2010; the order states that snares ‘must be firmly staked to the ground or attached to an object in a manner which will prevent the snare being dragged by a captured animal.’

Stake puller

This can be a purpose-made lever to extract stakes from the ground, or some other device that can be used to the same effect. In light soil you can get stakes out after a few knocks with a lump hammer, and this is neater in grass or in a standing crop. But carrying a stake puller ensures you never have to leave a stubborn one behind. We have found that a single, long-handled man-hole cover lifter works brilliantly for this purpose. The lifter we use has a J-shaped hook on one end, and a D-shaped handle on the other. The hook-end is used to tap and loosen the stake. Then hook through the welded ring, and pull vertically upwards using the handle. For particularly stubborn stakes, pass the hook-end through the welded ring, and lever upwards, pressing the D-shaped handle into the ground. The man-hole cover lifting tool is also very effective at inserting and extracting corkscrew-type anchor stakes.

Fixings

Ideally the snare terminates in a robust terminal swivel which can be attached to the anchor using a D-shackle. The D-shackle should be tightened with a pair of pliers, but beware of stripping the threads by over-tightening. Some snares are sold with unfinished cable ends, intended to be pushed through the anchor point and fastened back to the snare using a special fastening plate with two slots. We regard this as a poor fixing, and discourage their use. If used at all, the two parts of the cable in each slot must be fed through in opposite directions, as shown on the packaging. The cable should also be deliberately kinked where it passes through the plate to reduce the risk of slippage. Even when properly fitted in this way, we think the risk of slippage is too high, and we see far too many cases of incorrect fitting. Also, a snare with unfinished ends has no terminal swivel, which we regard as essential. So we strongly favour a robust terminal swivel and D-shackle fixing.

Get your FREE fox snaring guide from the GWCT team

Simply enter your email address below to download your essential free guide.

What's inside your FREE fox snaring guide

What's inside your FREE fox snaring guide

✓ Fox control: Is it important?

✓ What are the alternatives to snaring?

✓ The main components of a well-designed snare

✓ Fox snares: Hardware vs practice

✓ Key controversies

Download free >